EV Charging Cable

EV Charging Cable

1. General Description

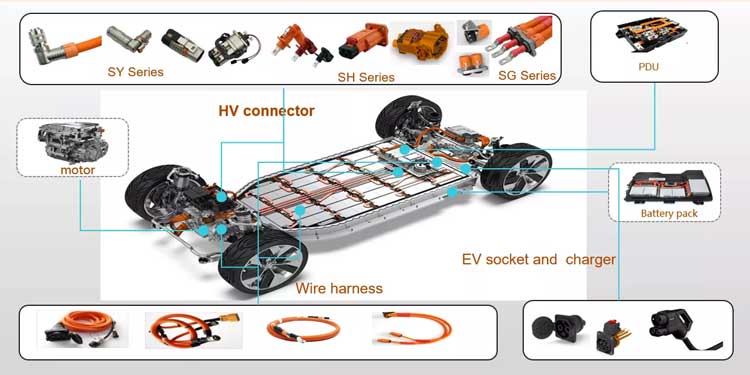

The EV charge electric vehicle wires and cables are mainly responsible for starting, driving, charging and discharging, air conditioning power, etc. It mainly includes battery systems, power trains, high-voltage electronic control systems, charging systems, high-voltage equipment, and wiring harness systems. Electric vehicle high-voltage lines are used to connect charging ports and batteries, battery interiors, batteries and engines and other components, as well as battery energy storage equipment and other fields, as a carrier of power transmission.

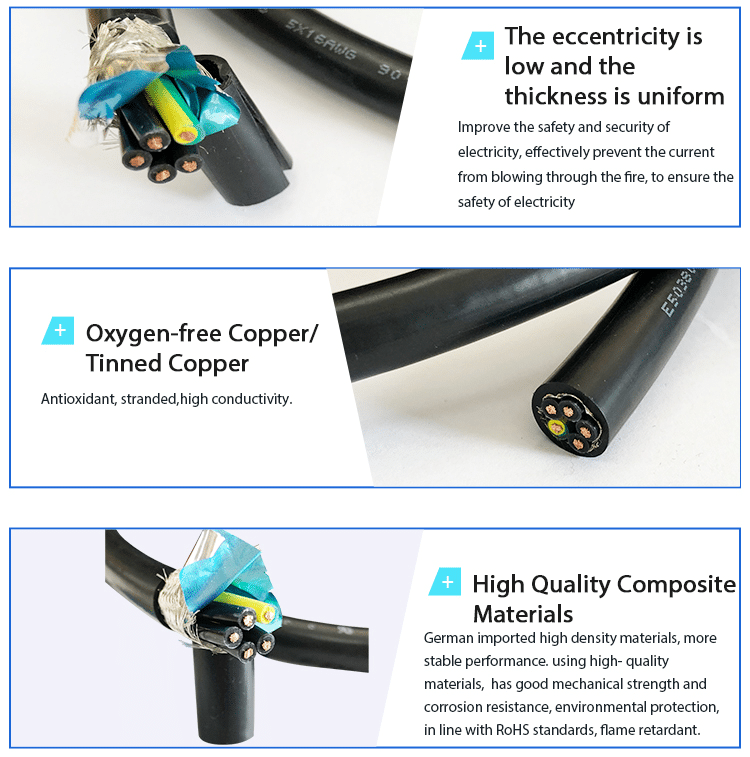

2. Cable Characteristics

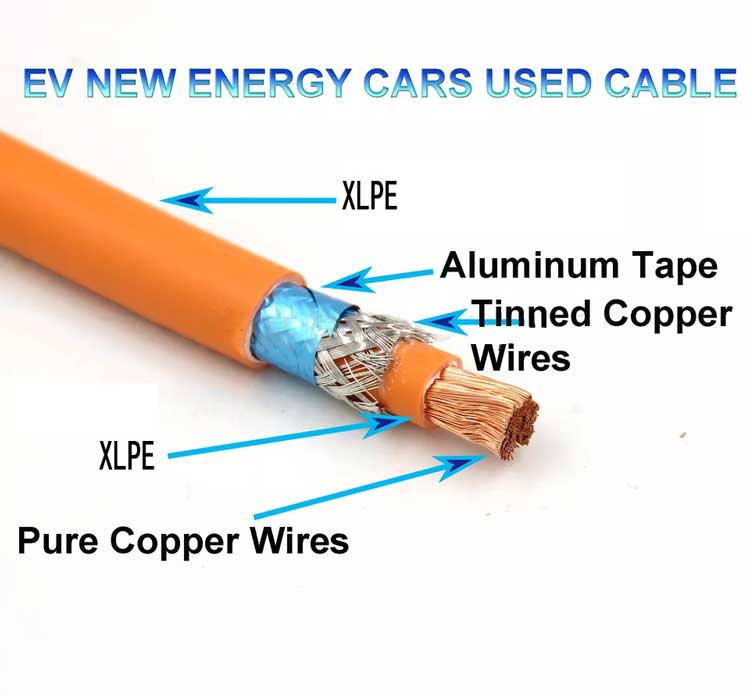

1.The product is soft and has a bending radius of less than 5D;

2. High and low temperature resistance, oil resistance, acid and alkali resistance, water resistance, wear resistance, cracking resistance, UV resistance;

3. Standard

GDEKRA Certificaed and test report available,

4. EV Charging Cable Supplier Data

Product name | EV cable |

Rated voltage | 1500v |

Temperature range | -40℃~125℃ |

Insulation resistance | Insulation resistance ≥1×109Ω at 70℃ (GB/T25085-2010) |

Compressive strength | AC-6000V/15MIN |

Insulator characteristics | XLPE (low smoke, halogen free, flame retardant) |

Aging test | long-term aging (125 ℃ * 3000H), short-term aging (150 ℃ * 240H), pressure does not break the skin. |

Oil resistance test | gasoline, diesel, motor oil |

Battery acid resistance test | The first cycle is 8h, the second cycle is 16h, the coiled wire does not expose copper, and the pressure does not break the skin. |

Ozone resistance test | 192h under ozone conditions, no insulation cracks (GB/T2951.21) |

Color | Orange-Red-Black |

5. Cable Delivery Requirements

1. The delivery length of the cable shall not be less than 100m, and the allowable length shall not be less than 20m.

2. The delivery quantity of short section cables should not exceed 10% of the total delivery length.

3. The error in length measurement shall not exceed ± 0.5%.

6. Packing and Shipping

1. Packaging: The cables are neatly wound on the cable delivery reel, with the cable ends tightly wrapped. The cable ends protruding from the reel are protected by nails, with a length of no less than 300mm and a weight of no more than 80kg. Short section cables are packaged in rolls. There is a product description label attached to the cable reel and the correct direction of rotation is indicated on the cable reel.

2. Transportation and Storage

a) Cables cannot be stored in the open air, and cable trays are not allowed to be laid flat.

b) It is strictly prohibited to drop cable trays containing cables from high places during transportation, and mechanical damage to cables is strictly prohibited.

c) When lifting packaging, it is strictly prohibited to lift multiple trays simultaneously. On vehicles, ships, and other means of transportation, cables must be securely placed and secured using appropriate methods to prevent collision or overturning.