UL Solar Cable for Photovoltaic Generating Equipments

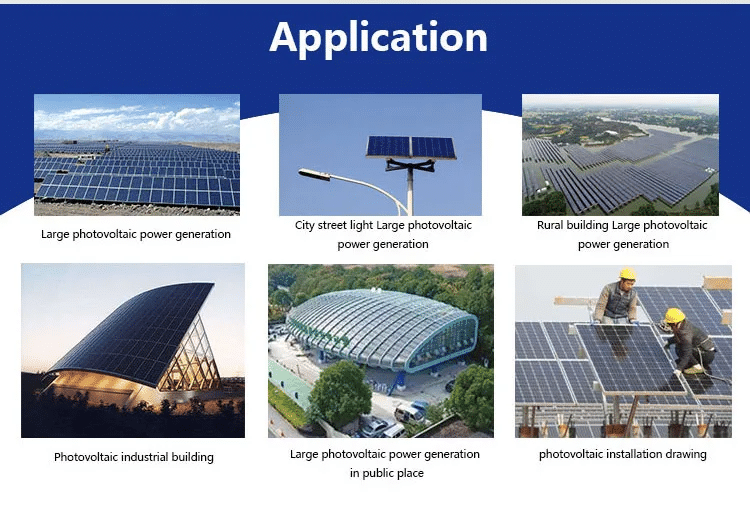

1.Application

The control cables for photovoltaic generating system is designed according to the peculiar ambient conditions and requirements, used in the signal and protection control loop.

This series of cable meet with the peculiar requirements of photovoltaic generating plant, suitable for the zone of high temperature, cold, grassland, moisture, salty fog, strong UV radiation, ozone and etc, also in consideration of anti – compact, tensile, animals bite, and use in higti building, etc.

2. Model and Name

Model: UL4703 – 2010

Name: Pliotovoltaic cable (UL) , Solar Cable(UL)

Applicable standard: UL4703 – 2010

3. Technical Data

Table1: The photovoltaic cables standard with PV UL4703-2010.

| Wire Specification (AWG) | Nominal cross sectional area(mm) | Conductor Structure | Outer diameter of complete cable (mm) | Conductor resistance (20℃) | ||

| 600V (no sheath) | 600V (with sheath) | 1000 & 2000V (with sheath) | ||||

| 18 | 0.823 | 27/0.20 | 4.4 | 5.1 | 5.9() | 23.2 |

| 17 | 1.025 | 32/ .020 | 4.4 | 5.2 | 6 | 18.3 |

| 16 | 1.31 | 27/0.25 | 4.7 | 5.4 | 6.15 | 14.6 |

| 15 | ).64 | 33/0.25 | 4.8 | 5.6 | 6.3 | 11.3 |

| 14 | 2.08 | 43/0.25 | 5.1 | 5.8 | 6.5 | 8.96 |

| 13 | 2.63 | 54/0.25 | 5.3 | 6.()() | 6.8 | 7.1() |

| 12 | 3.31 | 48/0.30 | 5.6 | 6.3 | 7.0() | 5.64 |

| 11 | 4.17 | 59/0.30 | 5.8 | 6.5 | 7.3 | 4.48 |

| 10 | 5.26 | 75/0.30 | 6.2 | 6.9 | 7.6 | 3.54 |

| 9 | 6.6 | 95/0.30 | 6.7 | 7.4 | 8.2 | 2.81 |

| 8 | 8.36 | 68/0.40 | 7.8 | 8.6 | 9.1 | 2.23 |

| 7 | 10.5 | 84/0.40 | 8.2 | 8.3) | 9.4 | 1.76 |

| 6 | 13.3 | 106/0.40 | 9.6 | 10.3 | 10.8 | 1.403 |

| 5 | 16.76 | 133/0.40 | 9.9 | 10.6 | 11.1 | 1.11 |

| 4 | 21.15 | 168/0.40 | 11 | 11 .90 | 12.4 | 0.88 |

| 3 | 26.65 | 210/0.40 | 11.6 | 12.3 | 12.8 | 0.7 |

| 2 | 33.62 | 268 / 0.40 | 12.7 | 13.3 | 13.8 | 0.55 |

4. PV Cable Characteristics

Ambient Temperature : – 40℃ – 90℃

Short circuit temperature: 5sec, 200CC

Rated voltage : 600V, 1000V and 2000V AC

Test of flammability : UL1581VM-1

Heat withstand, cold resistant, anti – abrasive, anti -UV, ozone resistant

High medianical strength, acid and alkali resistant, chemical products resistant

Service life up to 25 years