EN Halogen Free Solar Cable

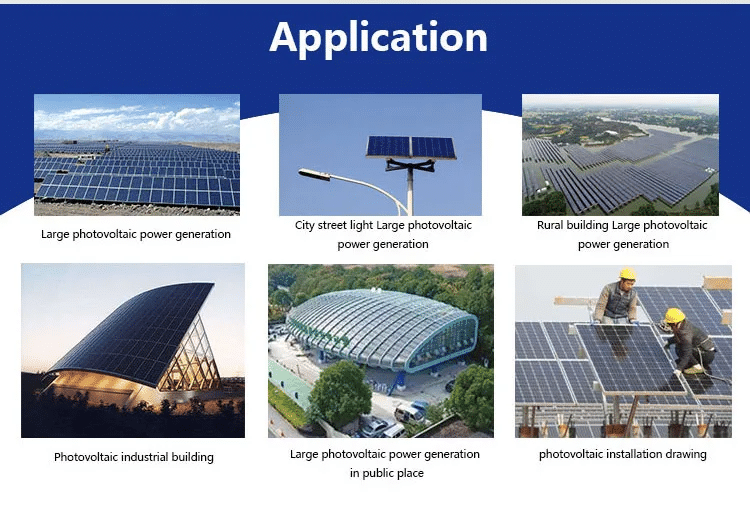

1.Application

This series of PV cable meet with the peculiar requirements of photovoltaic generating plantable for the zoneof high temperature, cold, grassland, moisture, salty fog, strong UV radiation, ozone and etc. Also in considerationof anti-compact, tensile, animals bite, andin high building…etc.

Solar Halogen-free cables for solar photovoltaic power generation equipment are designed based on the special environmental conditions in which photovoltaic power generation equipment is located, and are mainly suitable for DC voltage terminals, outgoing connections of power generation equipment, and bus connections between components. These products are based on the most advanced photovoltaic cable standard in the world, EN50618:2014.

2. Model and Name

Model: HIZ2Z2-K

Name: halogen free cable for photovoltaic equipment

Applicable standard: EN50618: 2014

3. Technical Data

Table1: Current carrying capacity of photovoltaic cables

Sectional cross area (mm2) | Installation method for current carrying capacity | ||

| Direct installation | Installation of single cable | Installation | |

1 .5 | 30 | 29 | 24 |

| 2.5 | 41 | 39 | 33 |

4 | 55 | 52 | 44 |

| 6 | 70 | 67 | 57 |

10 | 98 | 93 | 79 |

| 16 | 132 | 125 | 107 |

25 | 176 | 167 | 142 |

| 35 | 218 | 207 | 176 |

50 | 276 | 262 | 221 |

| 70 | 347 | 330 | 278 |

95 | 416 | 395 | 333 |

| 120 | 488 | 464 | 390 |

150 | 566 | 538 | 453 |

| 185 | 644 | 612 | 515 |

240 | 775 | 736 | 620 |

Note:Ambient temperature: 60c ( please see table 4 for other ambient temperature), highest temperature of conductor:120C

Table2: Size and Insulation Resistances

| Number of conductors and nominal cross sectional area (mm2) | Thickness of insulation layer (mm) | Thickness of sheath (mm) | Upper average limit of outer diameter (mm) | Mini insulation resistance at 20℃(MΩ.Km) | Mini insulation resistance at 90℃ (MΩ.Km) |

| 1 X 1.5 | 0.7 | 0.8 | 5.4 | 859 | 0.859 |

| 1 x 2.5 | 0.7 | 0.8 | 5.9 | 691 | 0.691 |

| 1 x 4 | 0.7 | 0.8 | 6.6 | 579 | 0.579 |

| 1 x 6 | 0.7 | 0.8 | 7.4 | 499 | 0.499 |

| 1 x 10 | 0.7 | 0.8 | 8.8 | 424 | 0.424 |

| 1 x 16 | 0.7 | 0.9 | 10.1 | 342 | 0.324 |

| 1 x 25 | 0.9 | 1 | 12.5 | 339 | 0.399 |

| 1 x 35 | 0.9 | 1.1 | 14 | 287 | 0.287 |

| 1 x 50 | 1 | 1.2 | 16.3 | 268 | 0.268 |

| 1 X 70 | 1.1 | 1.2 | 18.7 | 247 | 0.247 |

| 1 x 95 | 1.1 | 1.3 | 20.8 | 220 | 0.22 |

| 1 x 120 | 1.2 | 1.3 | 22.8 | 221 | 0.221 |

| 1 x 150 | 1.4 | 1.4 | 25.5 | 206 | 0.206 |

| 1 x 185 | 1.6 | 1.6 | 28.5 | 200 | 0.2 |

| 1 x 240 | 1.7 | 1.7 | 32.1 | 198 | 0.198 |

Table3: The conversion factor of rated current under different ambient temperature

| Ambient Temperature℃ | Conversion factor |

| up to 60 | 1 |

| 70 | 0.92 |

| 80 | 0.84 |

| 90 | 0.75 |

Table4: Impact test data

| Cable diameter (D) mm | Weight of hammer | Weight of middle steel sheet | Height mm |

| D<15 | 1000 | 200 | 100 |

| 15<D< 15 | 1500 | 200 | 150 |

| D>25 | 2000 | 200 | 200 |

4. PV Cable Characteristics

Ambient Temperature : – 40℃ – 90℃

Highest Cable Temperature: 120℃

Insulation Res i stance : > 1859 – 200MΩ .km at 20c, >0.859-0.200MΩ .km at 90c

Rated voltage: UO/U = 600V/ 1000V AC, 1500V DC (conductor, conductor, unearthing system)

Test voltage : 6500V, 50Hz / 5min or 15000V DC ;

Long time DC withstand voltage: 240h, 1. 5KV at 85℃Surface resistance of sheath: >109MΩ;

Smoke density: Light transmittance > 60%

Operate under high temperature, not melt down, not flow;

Pass the test of burning single cable as per IEC 60332-2 – 1

Heat withstand, cold resistant, anti – abrasive, anti -UV, ozone resistant

High medianical strength, acid and alkali resistant, chemical products resistant

Service life up to 25 years

Short circuit temperature: 5sec, 200CC