Production & Inspection

Multiple specifications and strict in-process inspection

China’s wire and cable industry sprouted in the 1930s, took shape in the 1950s, and rose rapidly from the end of the last century to the nearly three decades of this century. With the development of society, generations of cable workers have moved forward through twists and challenges, and with the establishment of a market economy and the deepening of reform and opening up, a mature industrial chain and complete industrial system have been formed, The entire wire and cable industry presents a diversified development pattern.

Conductor Drawing

Copper and aluminum rods are subjected to wire drawing and annealing on wire drawing machines and annealing equipment. High precision equipment and strict process control are used to ensure uniform size, stable and reliable performance of the drawn single wire, using high-tech nano residual diamond diamond molds combined with contact brush transmission high current annealing technology.

Wire Twisting

Twist several single wires of the same or different diameters together in a certain direction and according to certain rules to form a whole stranded wire core.

Insulating-Extrusion

A layer of insulation is formed on the surface of the conductive wire through equipment such as extruders, thereby achieving the purpose of insulation.

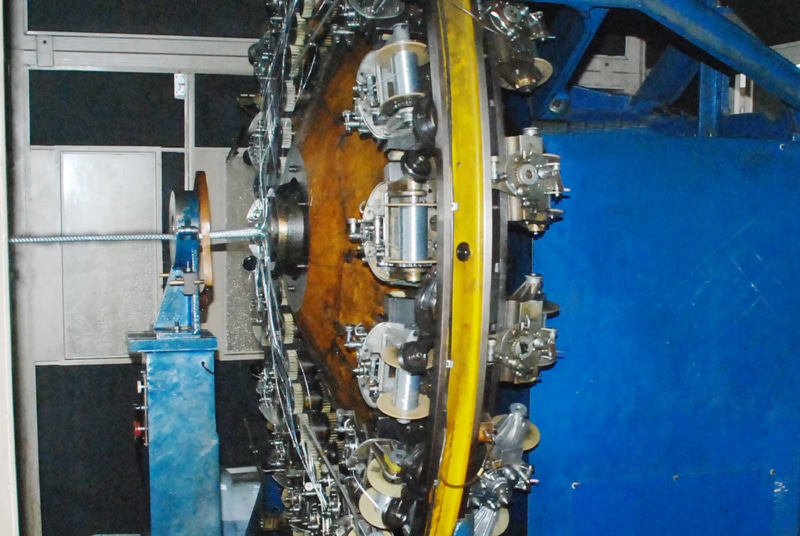

Braiding

There are mainly two types: copper wire and steel wire. The function of copper wire weaving is to prevent external electromagnetic interference and play a shielding role. Eliminate the shielding effect of the surface potential of power cables. The shielding effect of safety protection is mainly used for grounding protection, reflecting leakage situations. The function of wire weaving: mechanical protection, withstanding longitudinal tension, and shielding external magnetic fields

1.Classification of weaving machines: according to materials – fibers and metals;

2. According to structure – vertical and horizontal

3. According to the number of spindles for speed 1, high speed, and low speed

4. Weaving machines: commonly used are 12, 16, 24, 32, 36, and 48 spindles

Armoring

The process of wrapping or twisting metal strips, wires, etc. according to certain rules, and applying inner and outer layers. Metal armor has the function of withstanding external forces and protecting cables.

Cabling

The process of twisting several insulated wire cores or unit groups in a certain direction and according to certain rules to form a cable core. Cable forming is also a process of twisting. In addition to lamination, the cable forming process also includes process steps such as cable filling and tape wrapping.

Outer-Sheath

XLPE & Multilayer-Extrusion

The sheath material is wrapped on the outer surface of the cable core in a certain shape by a precision temperature control and professional designed mold combined with an extrusion machine, so that the processed product can meet certain processing requirements.