Rail Transit Cable Railway Vehicle Cable

Dedicated DC Special Cable For Rail Transit

1. General Description

The special rail transit cable are suitable for power transmission and distribution in the line. It can be laid indoors, outdoors, in tunnels, cable trenches, pipelines, flammable and severely corrosive environments. The cable can withstand strong mechanical external forces, and has low smoke, zero halogen, ant, rodent, waterproof, sun resistant, UV resistant, and low temperature resistance properties.

2. Cable Characteristics

1. Rated voltage: Uo/U (Um): 26/35 (40.5) kV

Note: – Uo is the rated power frequency voltage between the conductor to ground or metal shield used in cable design

– U is the rated power frequency voltage between conductors used in cable design

– Um is the maximum value of the “highest system voltage” that the device can use

2. Voltage test

– Test voltage: 91kV

– Time: 5 minutes

3. Partial discharge test

– Test voltage: 36.33kV (1.73Uo)

– No detectable discharge at a sensitivity equal to or better than 10pC

4. Maximum conductor temperature of the cable

– Normal operation: 90 ℃

– Under short-circuit conditions (maximum duration of 5 seconds): 250 ℃

Noted:D is cable outer diameter

| ITEM | Single Core | 3 Cores Armor | ||

| No Armor | With Armor | No Armor | With Armor | |

| Minimum cable bending radius during installation | 20D | 15D | 15D | 12D |

| Minimum bending radius of the cable near the connection and terminal | 15D | 12D | 12D | 10D |

3. Models and Specifications:

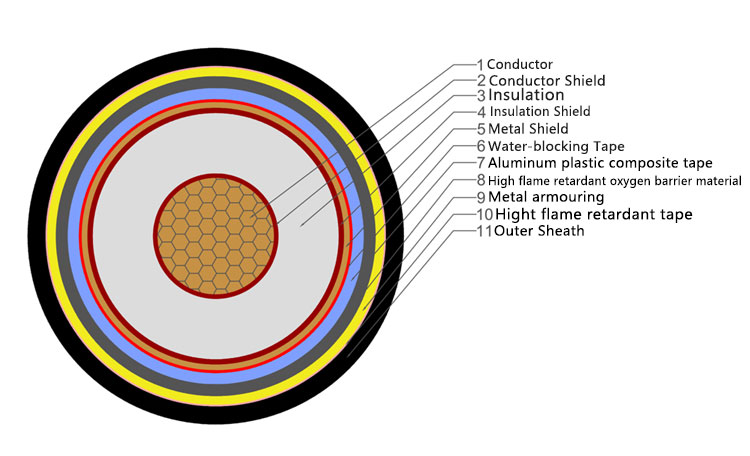

4.Construction

5. Standard

GB/T12706.3-2020 Power cables with extruded insulation and accessories for rated voltages from 1kV (Um=1.2kV) to 35kV (Um=40.5kV) – Part 3: Cables with rated voltages of 35kV (Um=40.5kV)

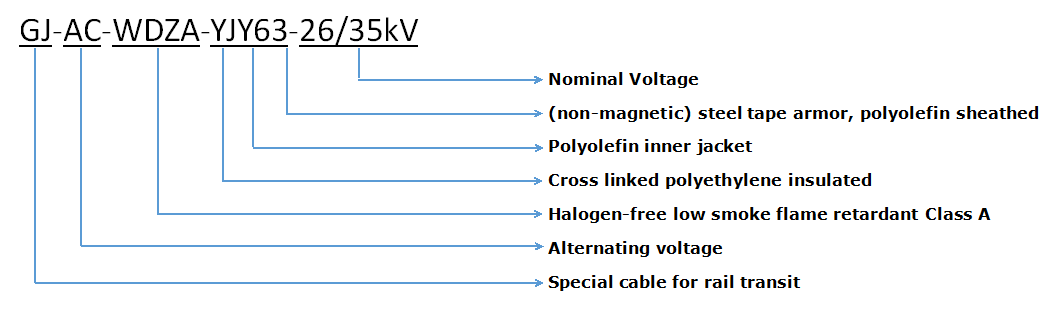

6. Rail Transit Cable Specification (GJ-AC-WDZA-YJY63-26/35kV)

| Cores and Cross Section Area (mm2) | Conductor Diameter (mm) | Insulation Thickness (mm) | Outer Sheath Thickness (mm) | Cable Outer Diameter (mm) | Cable Weight (kg/km) |

| 1*50 | 8.2 | 10.5 | 2.5 | 46.7 | 2797.44 |

| 1*70 | 10.2 | 10.5 | 2.6 | 48.9 | 3139.64 |

| 1*95 | 11.6 | 10.5 | 2.6 | 50.3 | 3435.83 |

| 1*120 | 12.9 | 10.5 | 2.7 | 51.8 | 3716.18 |

| 1*150 | 14.5 | 10.5 | 2.7 | 53.4 | 4160.87 |

| 1*185 | 17.5 | 10.5 | 2.8 | 56.6 | 4735.22 |

| 1*240 | 18.6 | 10.5 | 2.9 | 57.9 | 5315.84 |

| 1*300 | 20.5 | 10.5 | 2.9 | 59.8 | 6068.51 |

| 1*400 | 23.8 | 10.5 | 3.1 | 63.5 | 7262.6 |

| 1*500 | 25.5 | 10.5 | 3.1 | 65.2 | 8376.89 |

| 1*600 | 30 | 10.5 | 3.3 | 70.1 | 9929.84 |

7. Cable Delivery Requirements

1. The delivery length of the cable shall not be less than 100m, and the allowable length shall not be less than 20m.

2. The delivery quantity of short section cables should not exceed 10% of the total delivery length.

3. The error in length measurement shall not exceed ± 0.5%.

8. Packing and Shipping

1. Packaging: The cables are neatly wound on the cable delivery reel, with the cable ends tightly wrapped. The cable ends protruding from the reel are protected by nails, with a length of no less than 300mm and a weight of no more than 80kg. Short section cables are packaged in rolls. There is a product description label attached to the cable reel and the correct direction of rotation is indicated on the cable reel.

2. Transportation and Storage

a) Cables cannot be stored in the open air, and cable trays are not allowed to be laid flat.

b) It is strictly prohibited to drop cable trays containing cables from high places during transportation, and mechanical damage to cables is strictly prohibited.

c) When lifting packaging, it is strictly prohibited to lift multiple trays simultaneously. On vehicles, ships, and other means of transportation, cables must be securely placed and secured using appropriate methods to prevent collision or overturning.